Joining metal by brazing became the method of choice when the bicycle was invented in the late 1800s. Early bicycle lugs were in fact pipe fittings, but greater strength was needed, so brass was used instead of lead base solder.

Soldering and brazing are pretty much the same process, flux is required to allow the solder or brazing material to flow. The difference is the melting temperature of the different materials.

Soldering takes place at 427 degrees centigrade and below. Brazing between 593 and 895 degrees centigrade. Different sources will give a slightly different range, but as silver and brass will both melt within the range for brazing, that is the correct term. Brass brazing or silver brazing,

Silver is often known as Silver Solder, but strictly speaking it is not soldering because the melting temperature is above 427 degrees. Silver brazing rods come in soft, medium and hard, the soft being at the low end of the temperature range, progressing to a higher melting point for the medium and hard.

Silver is more expensive as it is for the most part silver, alloyed with other materials such as cadmium, or nickel. The price of silver brazing rods, will fluctuate with the price of silver on the Precious Metals Market.

Brass is already an alloy of copper and zinc, other materials will be added to give desired characteristics, like flow properties and workability. Brass melts at the higher end of the brazing range.

Often silver brazing is quoted as being best for lightweight bicycle frames because it melts at lower temperature. However, in the hands of a novice it is just as easy to overheat a joint using either silver or brass. In fact if you overheat a joint using silver, the silver will no longer flow, and the joint will have to be torn apart, thoroughly cleaned and start all over again.

Most framebuilders become proficient in either silver or brass, but my guess is, only a few totally master both. I became proficient with brass, but never built a complete frame using silver. The only time I used silver, was for brazing water bottle bosses, and top tube cable guides. The reason: Using the higher temperature brass would put a slight ripple in the thin un-butted part of the tube that would show after painting.

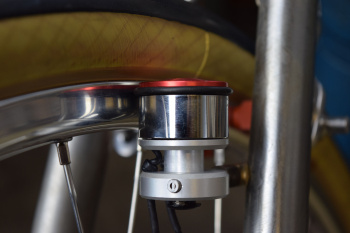

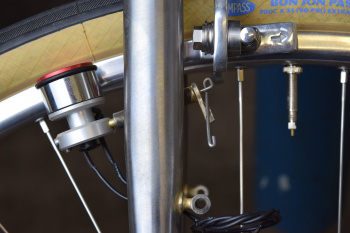

The traditional front and rear drop-outs, (Campagnolo for example. (picture left.)

The type where the front fork blade, chainstay and seatstay are slotted to take the drop out, have to be brass brazed.

Silver will not fill in the gaps, or fill the hole in the end of the tube. So even a builder who uses silver for the main frame will use brass for this type of drop-out.

Silver requires closer tolerances for example where the tubes fit in the lug. My method of altering the angle of the lug with a small hammer as I brazed, could not have been done with silver. The steel lug had to be at a bright red heat in order to be malleable enough to reshape. This would be too hot for silver.

Brass historically has always been used in Europe, which of course includes the UK where I learned to braze using brass. As a framebuilder becomes proficient at brass brazing, he learns to braze a joint cleanly, and not spill globs of brass over the edges of the lug. If this happens the builder will spend hour’s hand filing the excess brass away. Possibly leaving behind ugly file marks.

Silver on the other hand is softer and the excess can be sand-blasted away, or even scraped away with a small penknife. The fine and intricate, sharp edge lug work carried out by the late Brian Baylis, could not have been achieved using brass. English builder Hetchins did some fine elaborate brass brazed lug work, but on close inspection the corners and edges are not as fine and sharp as one can achieve with silver. (Baylis below left. Hetchins below right.)

Silver brazing bicycle frames on the scale it is used today is an American development that can be traced all the way back to the Schwinn Paramount. Read the history here. One of the reasons the Schwinn Paramount was built using silver, was the easy clean up.

The intricate Nervex lugs used (Right.) would have been a pain to brass braze cleanly.

Many of the early American builders were influenced by the Schwinn Paramount, and a few even apprenticed there.

Brass or Silver? Both have their own advantages and disadvantages. Both require different skill-sets.

I could never have done what Brian Baylis did, and on the other hand, he could not have built the number of frames I built using the methods he did.

Brass is more suited to production, silver is more suited to the artisan builder, custom building frames one at a time.

In my opinion, brass in many ways is more forgiving from a workability standpoint. For an absolute beginner, don’t be misled into thinking silver is easier.

Try brass brazing a few pieces of scrap metal together. You will have a lot of fun for not too much money. And a lot less heartache, than spending a ton of money by plunging straight in, and trying to silver braze a frame with little or no experience.